About – This article provides a solution to resolve the global water crisis. Please consider viewing the article on your desktop/laptop/tablet for higher resolution images.

Article Sections

- Introduction

- Learnings (with references)

- What is needed?

- The idea (Part 1, Part 2, Part 3)

- What works well for the idea

- Modified covered hopper car

- River location selection to withdraw and deposit the cargo

- How much water can be moved? Let’s do some math

- Dealing with water losses after its unloading

- Is this economical? Let’s talk money

- Some Q&A

Introduction – The effects of climate change are all around us and they continue to worsen. A significant proportion of the effects relate to water. Either too much of it in a short period of time resulting in intense downstream flooding or too little of it over extended periods resulting in a never ending drought. Water wars between states and countries are expected, inequality poised to worsen and instability would ensue. Further, the rapid melting of polar icecaps and resulting increases in global ocean levels only adds to the trouble ahead. The situation is grim all over the planet and novel solutions are immediately needed. There is a need for solutions that are easy to implement with current existing infrastructure, do no harm and give humanity the time it needs to get things in order.

While effective water conservation, recycling, tapping the ground water and piping water from distant places remain an option to tackle a prolonged drought, what do we do when we exhaust them? While sponge cities, more dams and taller dykes could counter an incoming flood, what do we do when those aren’t enough to contain a deluge? With the polar ice caps melting rapidly, how do we reverse a continuous rise in global sea levels?

Here, we present a novel solution to address these challenges with a singular idea. At its core, the challenge can be distilled down to managing effective movement of water from an area where there is excess to where it is limited. With this understanding in mind, we tried to crystallize the problem via various detailed learnings and worked to provide a solution.

Below are some of the learnings we gathered during this work and idea development phase (with references at the end of the article).

- In general, there is a significant resistance by communities to give up their water (surface or ground) for others.

- Creating an array of pipelines, dams and more have always been considered as a solution to alleviate water scarcity, but are not extensively implemented at a large scale.

- Damming the surface water away prevents fish migration, robs the crucial sand and silt that is essential for fertile downstream and the world is moving away from them.

- Water is the most dirty just after heavy rainfall as storm drains and sewage plants may overflow.

- Pollution in major rivers in the United States has reduced significantly after the passage of clean water act in 1972 along with concerted action by upstream residents and communities.

- Dirt acts as a natural cleanser preventing pollutants from entering the groundwater.

- Rivers contain groundwater too, which takes longer to fill up if drained excessively.

- Fountains are very useful part of water bodies with benefits towards aeration, removing odors, control algal growth and more.

- With reductions in available water and its diversions away from farming, our food security could be severely impacted driving global hunger, political instability, migrant crisis and unrest.

- Lack of water pits cities, farmers, conservationists and tribes against one another.

- Climate change will affect the intensity and frequency of precipitation. Excess in some years (in a short span of time) and close to none in another (for a prolonged period of time).

What is needed?

- A nimble yet effective solution that is capable of quickly moving water from an area of availability or excess to an area of need.

- A solution that can be quickly implemented at scale, using current infrastructure with manageable cost.

- A solution that doesn’t deplete just one area to feed the need of a nearby growing city.

- A solution that allows us to store water when it is excess, for use when there is none.

- An adaptable solution that aids all other current strategies.

The Idea

Herein, we present a novel solution of directly transporting water (surface water or ground water) from flowing rivers by filling empty freight cars over rail bridges built above them and unloading the water onto perennial river beds that lead to an existing reservoir, a water treatment plant or a distribution facility. Drought relief by transporting water in trains is not new, but how to do it effectively is. Let’s explore this idea in depth.

The proposed idea consists of three parts-

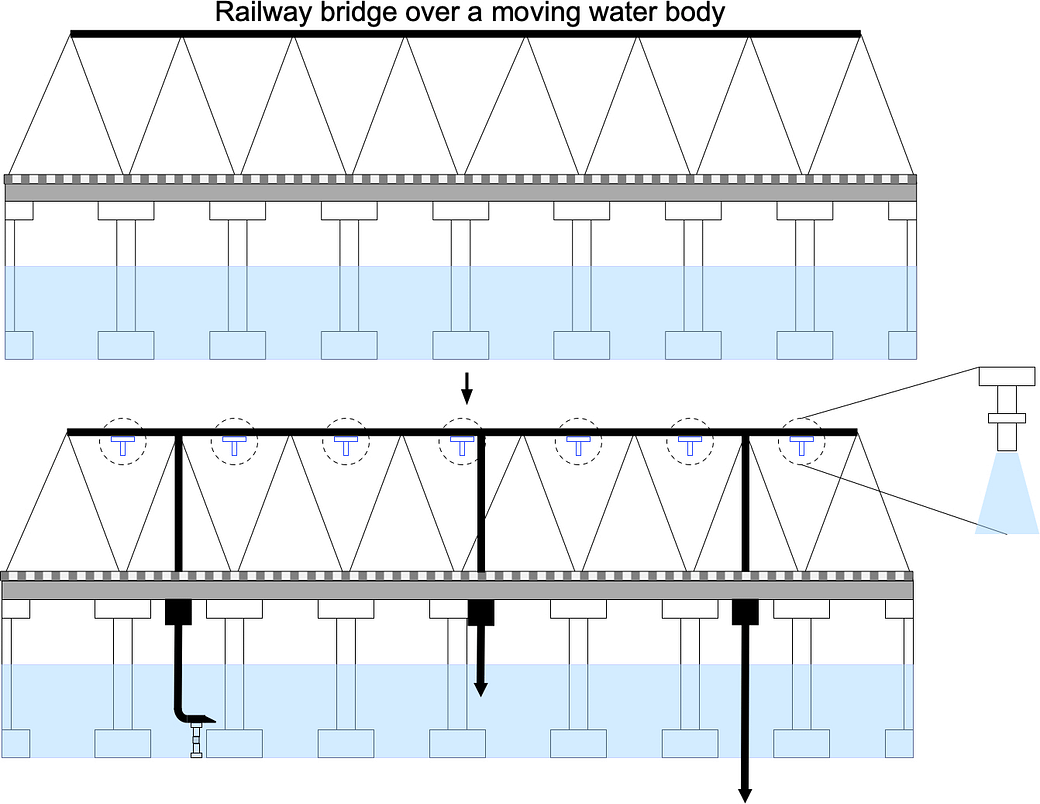

Part 1: Retrofitting current rail bridges above flowing rivers with high pressure dispensers that can fill up empty freight cars moving below them. Depending on the quality of the water and the level of the flowing river below, either ground water below the river bed or surface water flowing above the river bed could be tapped (while doing minimal harm to the river ecosystem). Rivers are all the rage after a heavy downpour, which might be a good time to collect water from them as long as good quality is retained. (Images not to scale)

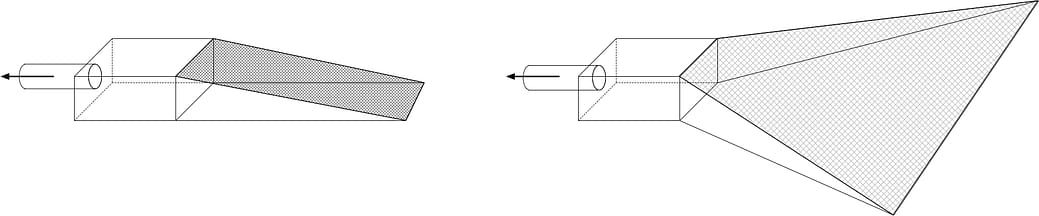

Design principle – Can we extract surface water as needed with minimal impact to the river wildlife? If the normal river velocity is approximately 5 mph, could we extract enough volume from the river without exceedingly high suction rate (maybe with a larger area of collection?

Part 2: Moving empty freight train cars below the retrofitted bridges with high pressure water dispensers that fill the moving empty train cars below. These high pressure water dispensers tap the water directly below them either flowing in the river or the groundwater below the riverbed. Speed of the train could be adjusted to allow appropriate filling of the rail cars with river water and flow rate of water increased to avoid loss of water on a windy day. Water could be filled into the moving trains next to the river as well, not just on the bridge. (Images not to scale)

Part 3: Water filled rail cars then empty their contents on a river bed that leads to an existing reservoir (that is stressed due to drought-like conditions) / a water treatment plant / distribution facility or a storage location that locks up the water in an underground aquifer for future use. The speed of dispensing could be adjusted to prevent damage to the stone/gravel infrastructure at the river bed site as necessary (Discussed later). (Images not to scale)

What works well for the idea?

- The idea taps the rail-roads, one of the only two man-made objects that know no national and international boundaries, allowing different states and countries to collaborate to manage an upcoming or ongoing crisis.

- Largest rivers in the world drain water from hundreds of thousands to millions of square miles of land and flow towards the oceans via narrow river passage ways that are just few miles across, making them the ideal places to tap into this resource.

- Railroads on bridges already cross large and small rivers, all of which could be retrofitted to tap the water flowing below them as needed.

- As the train could navigate through multiple railroad bridges built above moving water bodies, they are not dependent on extracting large amounts of water from a singular location. Multiple sources of water can be tapped to fill up the freight trains as it runs on its course.

- The water stored within the freight cars could be deposited at a particular location such as a water treatment plant or on a river bed that leads to a storage reservoir. This could cut down the distance travelled to deposit the cargo and utilize existing geography to solve the problem.

- In the moment of an incoming flood, large scale efforts to remove water from the river downstream before it swells, overflows its banks and washes away human infrastructure is a possibility.

- Climate change is likely going to exacerbate heavy precipitation and snow storm events across the world. Water from this deluge could likely be saved and stored via this route.

- This approach might face lesser resistance by local communities who are wary of pipelines extracting large amounts of their water resources for another, or a new dam that might submerge them.

- Unlike gravity fed canals to disperse water, transport of water via a freight cars could move in both directions.

- Water transport via trains can proceed while larger pipelines continue to remain under construction.

- There is a possibility to use a hybrid of rail, pipeline and river based transport to move water to an area of need (Rail – Pipeline – River hybrid transportation) or (Pipeline – Rail – Pipeline – River hybrid transportation)

- Freight volumes in the United States have been falling due to ongoing trade war. Could this help revive the industry?

The future weather patterns promise only irregularities with prolonged droughts and intense precipitation events. We need infrastructure adjustments that allow us to adapt to an ever changing world.

Modified Covered-top Hopper car

As the solution described here requires filling up of freight cars with river water from the top, on the go, and their unloading from the bottom, we looked into the wide array of freight rail cars that could allow this arrangement. Open-top hopper cars are frequently used to transport goods such as coal, sand, gravel and more in open air containers with gravity based unloading from the bottom. However, for more environmentally sensitive cargo such as wheat or soybean, covered top hopper cars are preferred. Covered top hopper cars protect their cargo from rain, dust and sand that might impact the integrity of the sensitive cargo. Both of these cars allow self-emptying and unloading of their contents from the bottom of the rail car via gravity driven discharge of cargo.

Transport of liquids such as water, crude oil and other polymer chemicals occurs via tank based cars which are filled at a specific location and dispensed at another from the same input. Considering the needs of the effort, it is likely that a modified version of covered top hopper car with a tank car interior has to be created. Current covered top hopper cars require an individual to manually close the top hatch once the filling is complete and open the bottom hatches to unload, both of which will likely have to be automated.

Figure: Covered top hopper car and tank car designs (freight rail wagons). Images copyrighted to Wikipedia: Creative commons license

Some considerations in the design of Modified Covered-top Hopper car:

- Automated closing of top hatch after filling of freight cars (on the go)

- Automated regulated discharge of water at the dispense site (on the go)

- Inner sealant lining of the modified covered top hopper car to prevent water leaks

- Consideration of the car design to deal with movement of water during motion

- Engine choice and management to properly regulate a freight train that is being filled up and emptied on the go

- Discharge units to the side of the hopper and not towards the bottom (open the one closest to the river)

River location selection to withdraw and deposit the cargo: A case study

Largest rivers of the world collect water from many thousands to millions of square miles of drainage basins and move them downstream into the deltas and the oceans. Largest rivers in the United States such as Colorado, Missouri, Mississippi, Columbia, Delaware and Hudson drain water from entirety of the continental United States and empty into the Pacific and Atlantic oceans.

While climate change continues to impact almost all of these river systems, none of them are as affected as the Colorado river system. Increasing demands from large population growth centers in the Southwestern United States, irregular precipitation, low snowpacks, rising temperatures along with declining inflows from the tributaries threaten to eventually empty the largest man made reservoirs in the United States (Lake Mead and Lake Powell on the Colorado river). All the other major rivers such as Mississippi, Missouri, Columbia, Delaware, Hudson seem to be in a much better shape. While these rivers still face fluctuations in year-over-year water levels, they do not carry the burden to singularly feed over 40 million people.

As a case study for this effort, we looked closely at the Missouri river. Draining almost 1/6th of the continental United States, this river has its origins in the Alberta and Saskatchewan provinces of Canada and drains large parts of Montana, Wyoming, North and South Dakota, Nebraska and Kansas into the Mississippi river at St. Louis, Missouri.

Figure: Colorado and Missouri river basins. Images copyrighted to Wikipedia: Creative commons license

During its course, large tributaries such as Yellowstone river, Little Missouri, Cheyenne, Platte and Kansas rivers join the Missouri river, adding fresh water into the system and raising its volume. Due to its propensity of regular flooding, the US Army Corps of Engineers have constructed a series of reservoirs on its course. However, there still have been events of flooding on the Missouri (years 2011, 2016 and more). With this proposal, in the years of surplus, the waters from Missouri river could be transferred to the Green river, a tributary of Colorado river or Colorado river itself via existing freight rail lines to deposit the water into Lake Powell and Lake Mead.

Figure: An overlay of the river systems within continental United States with the freight train lines. The light blue lines on the map correspond to Union Pacific freight rail lines. Red denotes the river basins. Grey lines denote the rivers. (Rail map: from LIFE AT THE SPEED OF RAIL – Van Alen Institute, River map: Images copyrighted to Wikipedia: Creative commons license)

Zooming in on the Missouri river on this overlay map of the river systems and freight train lines within the continental United States, we can see that the river on its journey from north to south, intersects with the Union Pacific freight rail lines at Omaha (1), Kansas (2) and St. Louis (not shown). In this proposed design, the water extracted from the Missouri river from Omaha or Kansas could be collected for deposition 600-800 miles to the west at the junction of the freight line and the Green river in southwest Wyoming or the Colorado river near Denver (Starred and circled). Deposition of the cargo in the Green river, a tributary of the Colorado river, would enable its travel hundreds of miles south through Utah to Lake Powell and subsequently to Lake Mead.

Figure: Intersection of freight lines (blue , yellow) and rivers (grey). 1: Omaha, 2: Kansas city, Starred and dotted circles: Intersection between the Green river, Colorado river and the freight line (Union Pacific). Red denotes the river basins. Images copyrighted to Van Alen Institute and Wikipedia: Creative commons license

Figure: Deposition of the cargo in the Green river/Colorado river would enable its travel hundreds of miles south to lake Powell and lake Mead (arrows). Green river and Colorado river intersections with the freight rail lines are all “starred” and “circled”. Salt river and railroad intersection is shown by an octagon. The intersection of Green river and railroad crossing in rural Wyoming is shown (Google maps satellite image). Images copyrighted to Van Alen Institute and Wikipedia: Creative commons license

Consequently, a few hundred miles ahead on the freight rail also lies the Salt lake, which is also in dire need to be filled up. Cargo trains could deliver the water to Salt lake in need, indicating the flexibility of the approach. Instead of piping water that relies heavily on a singular location to deliver to another, this approach opens up the flexibility to extract and deposit water at will across the continent i.e., the possibility to transport water from longer distances beyond the Missouri river to fill up Lake Powell and Lake Mead (such as Mississippi river intersecting freight lines at St. Louis).

This idea instantly opens up entire countries and continents to collaborate water transportation from an area of excess to an area of limitation.

Design Principle for location selection – Can we keep them away from population centers to prevent traffic jams at railroad crossings?

How much water can be moved? Let’s do some math.

With trains now stretching over 3 miles and with 300 wagons, the total projected capacity of a train may now stretch into 8 million gallons or around 25 acre feet. 40 trains per day could move 1000 acre feet, which in a year could move around 400,000 acre feet of water, similar to the amount of water a pipeline constructed was expected to draw from the Missouri to replenish the dwindling resources in California. Pipeline from Missouri was expected to draw 600,000 acre feet of water per year.

Please note: The calculations above represent an optimistic scenario. The longest trains in regular use contain around 200 cars, which could likely carry 16 acre feet per train.

Extraction rate – On a 500 feet long bridge, connected with 51 dispensers, 10 feet apart, where the freight train with 200 wagons, each wagon 50 feet long moves at a speed of 20 feet per second, we would need to dispense water at a rate of 200 gallons per second per dispenser to fill a 26000 gallon freight container by the time moves over the bridge. The dispensing must continue for over 1.4 hours to fill the 200 wagon train with over 5.2 million gallons of water. The flow rate of Missouri river at Omaha at this moment is over 645,868 gallons per second, significantly higher than needed to fill the freight train with 5.2 million gallons of water (10,000 gallons/second in total).

Resolving power requirements to pump the water: Case study (Union Pacific Missouri River Bridge in Omaha) – Hydraulic pumps are often used to pump water uphill, increasing its potential energy on its way up. In order to pump water from the river flowing below the bridges and dispense them into moving freight train wagons, it is likely that similar hydraulic pumps will have to be used. Our initial analysis indicated that a realistic approach would be to include a pump for every dispenser, thereby reducing the power requirement for each pump and the possibility to buy off the shelf pumps for this work.

Figure: Union Pacific Missouri River Bridge in Omaha. Water level is 60 feet below the bridge. Images copyrighted to Wikipedia: Creative commons license

Taking the example of the Union Pacific Missouri River Bridge in Omaha, we calculated the power requirements to pump 200 gallons per second of river water at different river heights. We identified three different conditions (low flow, high flow and over flow) and estimated the power required by operating hydraulic pumps to move the water. The three flow conditions also generate three different differential head levels of 80, 55 and 30 feet (24.4, 16.8, 9.1 meters) which were used for calculations (Differential head: Distance between the dispenser and the surface of the river).

Pump Power P(kW) = q(m3/hr) x ρ(kg/m3) x g(m2/s) x h(m) / 3600000

P(kW -Shaft) = P(kW) / η

- Flow rate (q) = 200 gallons per second = 12000 gallons per minute = 2725.5 m3/hr

- Density of fluid (ρ) = 1000 kg/m3

- Acceleration due to gravity (g) = 9.81 m/s2

- Differential Head (h) = 24.4, 16.8, 9.1m

- Pump efficiency (η) = 70%

|

Low flow |

High flow |

Over flow |

|

|

Pump Power (kW) |

181 |

125 |

68 |

|

Shaft motor Power (kW) |

259 |

178 |

97 |

These results indicate that the worse the flooding gets under a bridge, easier it is to move larger quantities of water at a fixed power consumption and accelerate the freight train to fill up same amount of water, thereby alleviating an incoming flood.

To meet these power and flow rate requirements, it is likely that electric centrifugal pumps which are routinely utilized in high volume, low pressure applications for low viscosity liquids such as general water supply, sea water transfer, firefighting and irrigation will be utilized. A number of vendors already sell pumps that operate to move water up to 40,000 gallons per minute who could be tapped (Gouldspumps).

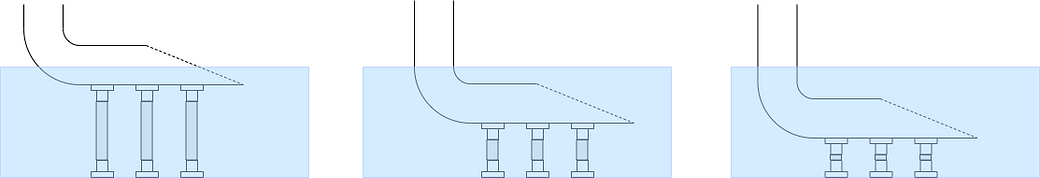

Dispense rate – 26000 gallons of water/freight wagon, with 10 dispensers per wagon (5 on each side), dispensed over 500 feet bridge (on the green river). At a speed of 25 feet per second (7.7 meters/second or 17 mph), the water needs be dispensed at a rate of 260 gallons per second per dispenser on either side of the wagon to empty the freight.

Dealing with water losses after its unloading

It is essential to minimize water losses after its unloading. Emptying freight wagons on to a dry river bed will likely lead to significant losses of water before it reaches its destination. Hence, effort must be made to dispense water closer to the site of destination, at the destination or dispense water into perennial rivers (facing acute reduction in flows), which likely still have saturated ground below them. Green river discussed above is a perennial river, originating in the Wind River Mountains of Wyoming and flowing through Wyoming and Utah before merging with the Colorado river. While the Colorado river is facing declining outflows, it still remains a perennial river in the earlier half of its journey.

Is this economical? Let’s talk money.

In a recent analysis, the cost of moving a gallon of water via rail to San Diego was expected to cost between 10 and 32 cents, unlike desalinated water which was thought to cost only 1 cent per gallon for the end users. While this cost seems high, the cost of construction of the desalination plant is approximately a billion dollars.

Of course, the effort did not include this new way of collecting and moving water on freight trains directly under river bridges and described the benefits of moving water by rail for the inland communities. A 200 wagon train, with 26000 gallon capacity per wagon, could transport around 16 acre feet per train.

- 16 acre feet per train = 5,214,000 gallons

- At 1 cent per gallon, we need to pump and ship the water at the cost of $52,140

Immediate costs–

- Retrofitting existing bridges with high pressure water dispensers

- Extraction equipment to collect water off the river

- Modified hopper car design (automated)

Longer term costs –

- Railway line electrification

- Electric wagons

- Excess solar electricity transported to drive the freight wagons

Initial investment

- $50,000-100,000 (environmental impact study)

- $5-10 million (pumps, labor, installation on the bridge, piping)

- $50 million (modified hopper car design and manufacture)?

Cost of pumping per train (Case study)

- 260 kW * 1.4 h * 51 pumps * 13.23 cents / kWh (electricity cost in Missouri) = $2456

Cost of transportation (Omaha to Green river, rural Wyoming / Kansas City to Denver) (Case study)

- Cost of biofuel for transportation cargo for 600-800 miles ($2.5/gallon) = $55,000

Our calculations indicate a slightly expensive cost to move river water cargo from Missouri river in Omaha to Green river in rural Wyoming / Colorado river near Denver for deposition. At the end of the day, it is likely that this system would be most effective to move water across shorter distances if dependent on a combustible fuel.

Some Q&A

Has this idea been tried before?

While not exactly, “Water train” headquartered at Oregon has unit trains consisting up to 110 rail cars which are bulk loaded at Water Train facilities at locations in areas east of the 100th Meridian for filling and dispensing directly near the customer. Water train claims to deliver up to 2.8 million gallons of water per train. There is also an in-depth article in railwayage.com that discusses transporting Columbia river water to California for use and its economics. Water trains are frequently used in countries such as India and Australia, but not in a fashion described here. (References)

How would you drive the trains across the country?

Modern locomotives are generally either diesel powered or electric powered that drive the freight wagons across the land from source to destination. It is imperative that we move towards cleaner sources of energy to drive these water freight trains to destination. While countries such as China and India have heavily invested in creating electric locomotive engines to drive freight trains, much of United States still relies on diesel/biodiesel powered locomotive engines, which needs to rapidly change. Driving these freight trains via diesel powered engines would be akin to trying to cure lung cancer with more smoking and we must use either electric or biodiesel based energy sources for the transport.

One source of energy could be the vast excess solar energy that California generates on a daily basis, which could be diverted to run electric engine driven freight trains to move water as described above. This utilizes one renewable energy resource to replenish a dwindling resource the state is in dire need of.

Will the water be okay traveling thousands of miles cross-country?

Water is likely to remain in continuous motion during the journey and a continuously moving water body may not spoil.

What is the best this idea could lead to?

- Another first line defense against rising flood waters.

- Identify creeks and communities most at risk for intense flooding and create avenues to remove surging waters before flooding ensues.

- Another front in global cooperation against climate change.

- The amount of water in the world is more or so constant, distributed between oceans, ground water, aquifers, surface water, polar ice caps and continental ice caps. With the polar ice caps melting, sea level is expected to rise by many meters by the end of this century. If done at extremely large scale, this idea could lock in water in deep underground aquifers and work to reduce the total flow of surface water into the oceans each year. This would in turn reduce the total sea level rise.

Alternate versions of this idea

Pipelines that closely follow railway tracks and empty into a river bed leading to a reservoir could be considered too. However, this also makes them stationary at a singular location.

Where could we go wrong?

- Impact on the river wildlife during extraction

- Impact on downstream communities

- Increase in vehicular traffic on the rail lines and on the bridges to extract and deposit water

- Water could be filled into the moving trains next to the river as well, not just on the bridge.

- Trains could be sped up on the dispense site (empty wagons faster)

- Laying down parallel tracks to help alleviate increased traffic on existing lines (as needed).

- Finding spots to extract and deposit river water

- Extracting too much water from one river location

- Discharge of water causing swelling downstream

- Removing surface water vs. ground water from the riverbed

- Global slowdown in rainfall making this investment worthless (unlikely)

Some unanswered questions

- When would be the best time to move the surface water from a raging river? Just after a storm, during the river swell?

- What are the drawbacks in dispensing high pressure water on to the surface of the bridge? Would it affect any existing infrastructure?

- Does this weight per freight car conform to the allowed Union Pacific standards?

- The freight trains may need to move to a much higher elevation during its journey? What are the challenges during that?

- Can the groundwater under a flowing river (within the unconfined aquifer) be tapped such that the surface water percolates and replenishes the groundwater as it is being removed?

- What are the short term and longer term impacts of such a removal?

- Can the water be decontaminated within the freight wagons while being transported to the destination?

An appeal to all the readers

Thank you for taking your time to read my article. Please help to make this idea more feasible and possible. Please help it reach the right people. Tennessee is flooded, California and Oregon are burning and North Dakota is running out of water. There is no time to waste.

Acknowledgements

The author is grateful to Srija DVLB for her support and help with the extraction rate calculations, Trevor Stebbins for verifying the pump power calculations. The author is also thankful to a previous mentor for his tips regarding the evaluation of the idea and tips to make it better. The author is also grateful to all the reviewers of the article and ongoing efforts by Atul Dhall towards a computational fluid flow model of the water extraction infrastructure suggested here.

Copyright: The work above is the original work of the author and may not be replicated without permission.

References

References for the “learnings”

3. https://www.americanrivers.org/threats-solutions/restoring-damaged-rivers/how-dams-damage-rivers/

4.1 https://www.scientificamerican.com/article/sewage-floods-likely-to-rise/

4.3 https://whyy.org/segments/swimming-in-the-wissahickon-isnt-so-idyllic-theres-poop-in-it/

5.1https://www.nola.com/news/environment/article_3ca75aaa-6ca9-11eb-8079-738fcb48460d.html

5.2 https://e360.yale.edu/features/on-the-delaware-a-promising-new-era-in-cleanup-of-an-urban-river

6. https://www.scientificamerican.com/article/how-dirt-cleans-water/

7.1 https://www.nationalgeographic.com/science/article/groundwater-pumping-killing-rivers-streams

8. https://www.floridaquatic.com/fountain-and-aeration-system/

10. https://www.hcn.org/articles/water-klamath-water-illegally-diverted-to-farming-during-severe-drought

11. https://www.epa.gov/climate-indicators/climate-change-indicators-heavy-precipitation

References for “What works well for the idea?”

1. https://www.washingtonpost.com/business/economy/railroads-are-slashing-workers-cheered-on-by-wall-street-to-stay-profitable-amid-trumps-trade-war/2020/01/02/dc757ed4-1603-11ea-a659-7d69641c6ff7_story.html

References for “modified covered top hopper car”

- Youtube video titled “MaxYield Co-op 100 Rail Car Loading Process”

- YouTube video titled “Rail Car Types and What They Carry” and “Rail Tank Car 101”

- https://www.gatx.com/wps/wcm/connect/gatx/gatx_site/home/rail+north+america/products/equipment+types/freight/covered+hoppers/plastic+pellet/pneumatic

- https://railroads.dot.gov/sites/fra.dot.gov/files/fra_net/3438/Filling%20Limits%20Presentation%20-%20Dennis%20Campbell.pdf

References for “River location selection to withdraw and deposit the cargo”

1. https://www.environmentbuddy.com/environment/the-most-polluted-rivers-in-the-us/

References for “How much water can be moved? Let’s do some math”

- https://www.watertrain.us/

- https://www.railwayage.com/freight/class-i/drought-relief-by-rail/

- 3. https://www.environmentbuddy.com/environment/the-most-polluted-rivers-in-the-us/

- 4. https://www.mcclatchydc.com/news/nation-world/national/article24741661.html

References for “Resolving power requirements to pump the water”

1.https://www.engineeringtoolbox.com/pumps-power-d_505.html

2. https://www.castlepumps.com/info-hub/positive-displacement-vs-centrifugal-pumps/

3. https://www.gouldspumps.com/

References for “Is this economical? Let’s talk money”

- https://www.electricchoice.com/electricity-prices-by-state/

- https://www.envstd.com/what-is-the-cost-of-a-phase-i-environmental-site-assessment/

- https://www.csx.com/index.cfm/about-us/the-csx-advantage/fuel-efficiency/

- https://www.tnstate.edu/extension/documents/BiodieselEconomics.pdf

References for “Some Q&A”